Vibrocore-D unit offers lower costs, faster results

A case study on coring on the Thames

Problem

For dredging works on the Thames, the Marine Management Organisation and the PLA, requires sediment samples be taken and analysed. When the dredge depths are greater than 1m, it is normal for samples to be required at dredge depth, which requires coring.

Traditionally, these cores have been obtained with a larger corer of the type used in an offshore environment. These are large expensive units which require a large vessel with a crane of A-Frame to handle. This results in a high cost to acquire the samples and delays due to the limited availability of such units.

Proposed Solution

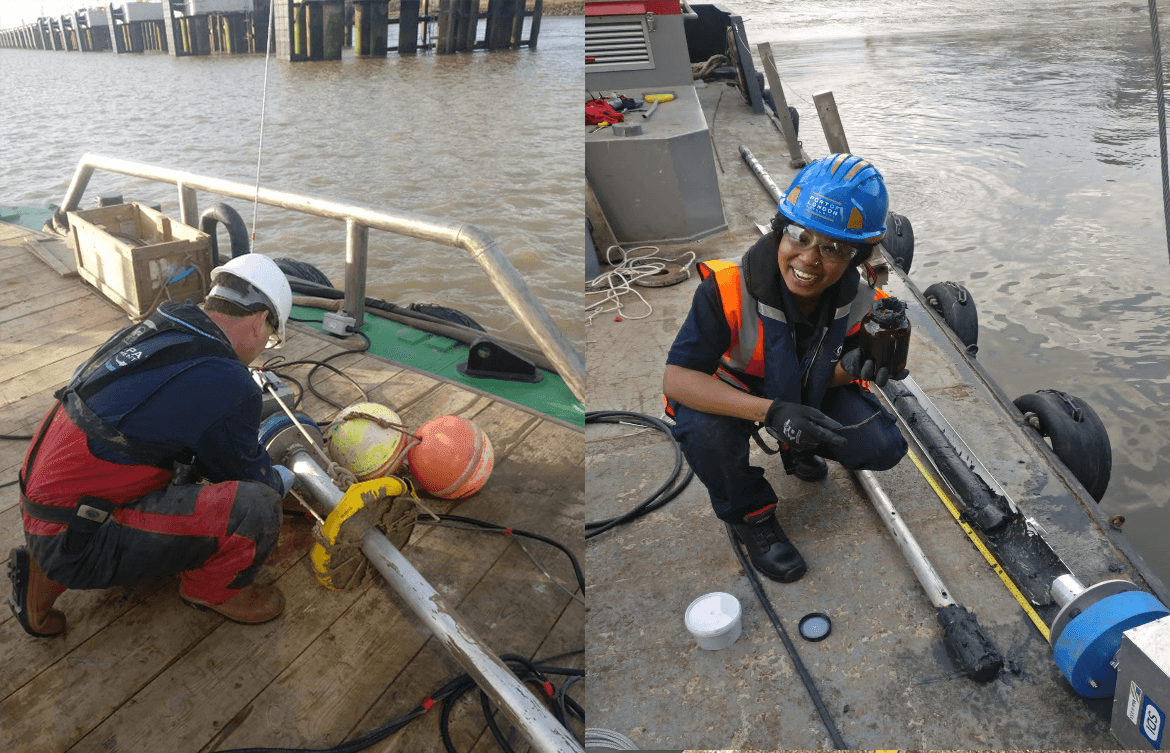

To provide a cheaper and faster solution, the PLA have trialled a small vibrocore unit. This is a small unit as shown in the image at top left.

Field Work

This is a case study looks at using this small unit on 3 coring sites on the Thames:

- A berth where cores were required ahead of maintenance dredging, which consisted of recent sediments, 2 cores, max core depth 1.9m

- A berth with had not been dredged for > 10 years and were the sediment was =<10yrs

- Sediment samples ahead of dredging for decommissioning a site (8 cores, maximum core depth 1.5m)

Results

|

Site |

Qty of core |

maximum core depth requested |

maximum core depth achieved |

Sediment Description |

|

1 |

3 |

1.9m |

1.4m |

The recent soft sediment cored very easily. Core catchers were required to stop the core slipping out. No re-attempts required as depth achieved within tolerance. 0-1.4m very fine sand and silt |

|

2 |

6 |

2.5m |

2.7m |

0-0.15: Brown/grey very fine sand and silt 0.75-1.25m: Grey muddy sand with gravel and some pebbles 2.25-2.70m: Sandy gravel with pebbles and chalk at the bottom |

|

3 |

8 |

1.5m |

1.5m |

0-0.75m Soft grey silt 0.75-1.5m Compacted black silt. |

Note, On site 3 some of the cores were over protective matting and there was insufficient depth of sediment on top, so these locations were moved. This would have been the case with a larger corer also.

Conclusion

The small vibrocorer unit was able to achieve the required depth of coring at all three sites and was a cost-effective solution.

The PLA have now purchased one of these units so that we have the resource on the Thames and will be able to quickly respond to customer needs.

Case study written by Mary Ajanaku